As the restaurant industry recovers and rebounds from the COVID-19 pandemic and prepares for a summer of hungry customers, owners and general managers are seeking opportunities to optimize areas of the business through technology and key automations.

When it comes to the restaurant maintenance and repair process, CMMS, or Computerized Maintenance Management Systems, have been the primary tool available to any business interested in facility management software. However, with lean teams and even leaner budgets, the painstakingly complex process of selecting, integrating, and onboarding a CMMS won’t work for most restaurant operators. Beyond the limitations of the tools themselves, the additional resources required to get the most benefit from your CMMS of choice ultimately diminish its ROI.

6 reasons why CMMS solutions won’t work for restaurant operators.

1) Hidden Costs

Some CMMS tools start at as low as $5 per month for membership. What a deal! Well, not exactly. Once onboarded as a customer, you’ll encounter the inevitable pile-up of markups – including but not limited to additional fees per work order, location, specific service providers, integrations, and more. Plus, markups on the actual cost of the repair per incident. Like most software, the low monthly price tag gets you in the door, but the upgrades (that come at a serious price) get you the functionality you’re looking for. In order to truly benefit from a CMMS system to actually accomplish your equipment repairs and maintenance goals, the basic version won’t suffice.

2) Time

As with any new software, a CMMS implementation requires extensive training and setup. What does that look like for restaurant operations and management? Onboarding onto a CMMS includes manually inputting all your data, reporting requests, existing service providers, and many more settings into the tool. Regardless of what your customer success representative says, “quick” and “setup” will not fall in the same sentence.

Even if you need help fast, you’ll still need to fill out every required form field for a work order within your CMMS software.

Once onboarding and training are complete, either one designated staff member or your entire team must stay up-to-date as new features, functions, and service incidents arise. Any lags and lack of updating will only hurt your process and further contribute to the tool’s inefficiency.

With industry-wide employment still struggling to return to its pre-pandemic scale, it is not ideal to take time away from your front-of-house team. Restaurants need all hands on deck right now. When a repair is needed, a line cook or general manager won’t be able to urgently take time out of their standard day-to-day to fill out dozens of fields, independently identify the issue, and submit a work order.

3) Taking Stock of Inventory

So you’ve selected a CMMS solution – now what? In order to accurately track all data inputs and the complete incident lifecycle, you’ll need a comprehensive inventory roundup.

Ah, there’s nothing better than having to lie on the greasy floor at the end of a long shift to look under your grill to take a photo of the nameplate to verify the make and model to upload.

95% of our customers don't have a complete equipment inventory for their restaurant locations when they begin working with our service.

Let us do the dirty work. Your staff does not want to build and maintain equipment inventories. On average, there are 65 pieces of equipment in a QSR (quick-service restaurant) or fast-casual restaurant, and 95 pieces in a full-service restaurant. Now multiply that across 5, 10, 15, or 50 restaurants. It’s a big job to create digital equipment inventories and very few restaurants are successful at manually doing this task themselves.

4) Analyzing Trends and Insights

Bad news: the automated data spit out by CMMS tools in your main dashboard won’t help you save. Without the ability to analyze these data points, you won’t be able to make actionable, measurable changes to your existing processes, nor have a clear plan for preventative maintenance.

Isn’t the definition of insanity “doing the same thing over and over again and expecting a different result?” If you’re repeatedly making mistakes in your R&M process, but you’re unable to pinpoint the source of these issues or inflated maintenance costs, then your process remains inefficient.

Identifying trends as a user is possible, sure, but intensely time-consuming. Whomever's shoulders this responsibility falls on will have to dedicate time and attention to making sense of this data, assessing trends, and asking all the right questions.

Are you paying fair prices for repairs?

Are you accurately making repair vs. replace decisions? Are you tracking asset downtime?

Are there differences in real-time incident history across your multiple locations?

Unfortunately, a CMMS won’t help you answer these questions on its own. We use past customers’ data to crowdsource common troubleshooting steps, compute average restaurant repair and maintenance costs by equipment and location, and much more. With 86 Repairs, you access the collective intelligence of almost 1,000 restaurant locations and 7,000+ incident tickets. With a CMMS, you only have access to your data, leaving you in the dark on industry benchmarks or how you’re comparing to other operators.

Without these answers and actionable insights at your fingertips, you’re likely to continue overspending – both time and money – on repairs.

5) Accessibility

The last thing a busy restaurant operator needs to remember is another password. While one CMMS log-in may not seem daunting, turnover and employment issues in the industry have never been higher. In addition to onboarding and training, do you really need another admin log-in to set up and inevitably have issues with?

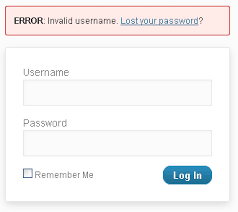

That dreaded error message. Even more infuriating when your HVAC is broken and the heat-induced delusion is setting in.

Some CMMS tools offer accessibility through mobile apps, but the actual user experience is still complicated and outdated. Think back to the last time something broke down in your restaurant. How willing, at that moment, were you to drop everything and plug information into a form only to have a failed internet connection, missing field, or other error?

6) Bureaucracy

If you’ve never worked with a CMMS package before, or any Software as a Service tool for that matter, the bureaucracy and red tape involved could come as a shock.

In moments of panic and crisis in a restaurant when a critical piece of equipment is down, the last thing your team wants to be focused on is navigating complicated software to document, diagnose, and collect data on the steps in the incident handling process. In heated moments, all that matters is getting the actual repair done. The dotted I’s and crossed T’s are secondary.

Let’s make this more concrete:

You’ve dispatched a vendor to fix a critical piece of equipment and a perfectly legitimate service provider could arrive at your door, only to have to refuse the job because your CMMS package required one field of information they were unable to provide or they weren’t part of the pre-approved list of service providers.

CMMS tools don’t advocate for a collaborative relationship with contractors; instead, they advertise putting pressure on vendors to get the job done quickly while marking up invoices and hourly rates. This type of arrangement could put unnecessary strain on existing service provider relationships.

With 86, there are people AND software involved in every step of the restaurant R&M process; a CMMS will not troubleshoot and find solutions the way a Customer Success Manager will. All this mess creates more tension and weaker relationships with service providers and your team alike.

The Better Solution

Luckily, 86 Repairs’ mission is to alleviate all the stressors outlined above for restaurant operators.

“86 Repairs brings efficiency, reliable data, and a dogged concern for resolution to the table.” – Andy Freivogel, Co-Founder & CEO of Science On Call

Our primary goal is to save you money and time on the restaurant R&M process.

We don’t take referral fees from service providers or mark up their costs in any way, so you can continue working with who you love.

There’s no additional management required from your end per incident either.

We manage every service incident directly with a service provider from start to finish, while keeping your team informed through each step of the process.

If your preferred vendors are not available, no problem – we leverage our network of trusted service providers to ensure quality, timely service.

We champion accessibility.

We’re just a text, phone call, or email away.

One popular CMMS tool advertises users’ “option to initiate, track and close work orders” and the ability to “communicate work order status.”

With 86, as jobs are dispatched, scheduled, and completed by our team, we deliver real-time updates so your team can focus on what matters most. Your team is no longer responsible for the manual tasks and cumbersome labor required to initiate, track, and close work orders.

With our Customer Success Managers available 24/7, 365 days a year, you’ll have a clear understanding of what equipment may only require troubleshooting, versus repairs or replacement. And all the while, we’re keeping track. Of everything. We summarize the most relevant data and trends within each location of your business, translate these numbers into actionable insights, and help you make more strategic decisions about your operations.

“We trust 86 Repairs, and we see every day the value they deliver to not only their customers but to our customers,” says 86 Repairs customer Andy Freivogel, Co-Founder & CEO of Science On Call. “We see 86 Repairs as allowing our restaurant customers to operate and grow with intent, and without the distractions of the traditional (and clunky) model of a giant sheet of names and numbers of various repair people: some of whom aren't reliable, don't invoice correctly, and don't track the service history of their own work. 86 Repairs brings efficiency, reliable data, and a dogged concern for resolution to the table.”