It is well known that restaurant labor and food costs have risen sharply in recent years, posing significant challenges to the industry. Though this has led to unique innovations in pricing, sourcing, and even operating systems in an attempt to protect margins, it has led to rising prices for consumers.

At the Restaurant Leadership Conference this past April, Technoheight presented its annual State of the Restaurant Industry Report. Based on market data, they showed that restaurants have squeezed all they can out of increasing prices for consumers, and this inflation is already directly contributing to decreased foot traffic. In Technoheight’s interpretation, continuing this strategy could cause more harm than good, and many operators have started to recognize this. Restaurant operators recognize that they need to be more innovative than ever before when it comes to finding opportunities to improve margins and control costs, which means Repairs & Maintenance (R&M) costs are finally taking center stage.

Despite being one of the largest truly controllable restaurant costs, addressing R&M spend has historically been difficult, as restaurant operators have fought for the proper visibility needed to understand it better.

You may call them Service Providers, Vendors, or Tradespeople, but ultimately they are the ones we call when equipment breaks and we need help in a pinch. In recent years, however, working with Service Providers has become increasingly challenging and expensive. Cost and quality can be unpredictable and as restaurant groups expand, establishing preferred service providers for each trade is difficult.

In this article, we’ll we aim to take a deeper dive and shed light onto the hidden costs of R&M that come from ineffective vendor relationships – with some of the most prolific areas being:

- The Misconceptions of Negotiated Rates

- The Challenges of Third-Party Channels

- The Cost of Excessive Vendor Dispatches and Repeat Visits

1. The Negotiated-Rate Fallacy

Just like in restaurants, labor for service providers is going up. This is a reflection of macro trends in the economy as well as the increasing shortage of skilled tradespeople. A common strategy for reducing spend with service providers is to negotiate rates with large providers to drive down costs. In some instances, this can be helpful. Repair quoting, for example, is commonly a paid visit – but with the right partnership these are something that may be negotiated down or out based on volume.

In the aggregate, however, fixed hourly rates rarely have a measurable impact on overall R&M spend and improved margins. Here are three reasons why:

- Hourly rates rarely predict the true cost of an engagement. While there is some predictability in time dedicated to routine tasks, ultimately there is substantial variation from provider to provider in how long it will be needed for a certain job.

- Focusing on hourly rates as the leading indicator of costs can lead to unproductive partnerships where “speed to resolution” and “first-time fix rates” are not aligned.

- Securing national rate schedules and covering all service categories is seldom possible given the fragmented nature and universal demand for trades.

So, what is the solution? Data! Specifically, data you can use.

Having access to market rates for common maintenance and break/fix scenarios is the secret sauce to optimizing your vendor network.

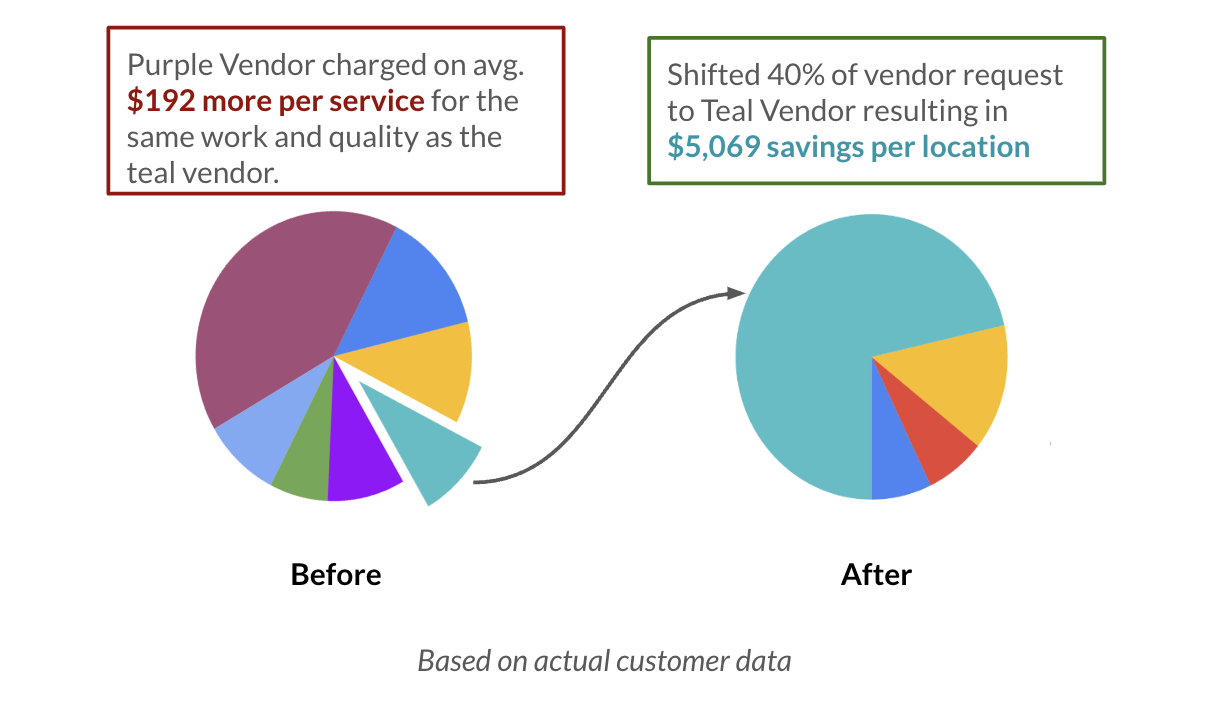

This is where an unbiased, vendor-agnostic solution, like 86 Repairs, brings hundreds of thousands of data points to establish benchmarks by market and service category, to provide you with predictive pricing to avoid overspending. Additionally, this fuels deep analytics, like in the chart below, which allows for true cost analysis, and vendor optimization, and drives better decision-making.

A Comparison of Vendors

86 Repairs prompts users with a wide range of automated savings insights, including but not limited to, quote reasonableness, troubleshooting, warranty validation, invoice variances, vendor quality, and as reflected above, true vendor cost comparisons.

2. Third Party Mark-Ups & Restrictions

A longstanding strategy for solving core restaurant R&M challenges has been to adopt vendor-centric CMMS or Vendor Marketplace Platforms. By doing so, restaurant groups have sought to improve outcomes through better data, vendor management, and organization of their R&M processes. However, many find that these platforms do not effectively cater to the true needs of restaurant operators.

Why Vendors tend to avoid “Third Party Channels”

From the vendors’ perspective, despite providing business development opportunities, CMMS and Marketplaces create operational challenges for many vendors. Because these platforms often require vendors to work directly through the platforms, it requires them to constantly manage multiple systems and communication channels. These challenges can lead to poor service, and thus, negative impacts on vendors’ reputations. Additionally, these platforms are largely funded by vendor participation, so vendors often have to pay subscription fees or accept invoice mark-ups.

In the end, it comes down to whether the best vendors truly need this incremental business, and the reality is that most do not. Given the shortage of service providers and universal demand across multiple vertices, the highest-rated service providers often push back against working through these platforms. The cost and friction to do so have historically not justified the return.

Why Third Party Channels don’t work for restaurants

There are three key areas that CMMS and Vendor Marketplaces have struggled to effectively solve to make them beneficial channels for restaurants.

Firstly, restaurant employees do not use R&M platforms regularly. Unlike a POS, they are generally accessed just a few times a month, yet, many CMMS and Vendor Marketplaces are built for facilities managers and technicians. As a result, the user interface does not cater to front-line restaurant staff very well, leading to poor adoption and usage which results in lower efficacy and unusable data.

Second, vendor choice is an essential part of controlling quality and cost. Because many CMMS and Vendor Marketplaces are built on networks there are inherent barriers to entry for service providers. This limits who restaurants can work with, and potentially prevents restaurant operators from being able to continue working with their preferred providers while also making it more difficult to recruit new, highly vetted vendors.

Lastly, restaurants pay more. Even when monthly costs are low or non-existent, a small margin on annual R&M spend adds up quickly. A $1.5 million establishment, with a 3.5% R&M line is likely paying over $200 a month in mark-ups alone – that’s $2,400/yr per location! Additionally, because these platforms monetize each transaction, there is an incentive to excessively dispatch vendors. As mentioned above, the impact of not having access to all vendors means a longer time to resolutions, poorer quality, and increased impact on top-line revenue and profit margins.

This is why the 86 Repairs platform was created. As a dedicated partner to restaurants, 86 Repairs does not monetize its relationship with vendors. Vendors do not pay incremental fees and invoices are never marked up. This is one of the ways we attract the best service providers.

Additionally, as a vendor-agnostic solution, 86 Repairs does not require vendors to work through its system. This empowers operators to leverage unbiased 86 Repairs performance data and work with any vendor they prefer.

In the end, greater choice and transparency lead to reduced costs for operators.

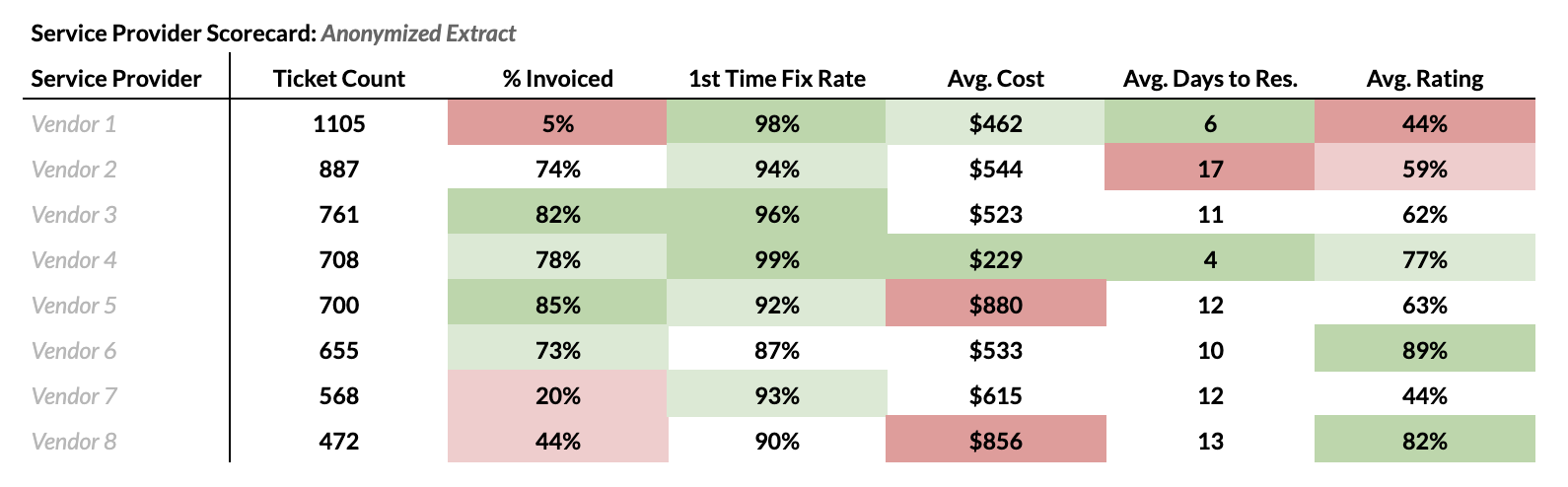

An 86 Repairs Vendor Scorecard

3. Excessive Vendor Dispatches and Repeat Visits

One of the greatest frustrations for finance and operations leaders is when a seemingly straightforward repair task leads to multiple visits - inflating costs and adding further delays to getting equipment running. What’s more, all too often it’s not discovered until the invoice arrives. This is a clear example of how the reactive status quo for R&M drives costs up for restaurants.

Why does this happen?

- Ineffective Troubleshooting & Warranty Workflows: Preventing vendor dispatches or “truck rolls” should be a core focus of any internal R&M process. By evaluating over 250,000 R&M maintenance tickets, 86 Repairs has identified that over 18% of them could have been solved through troubleshooting, or were under warranty, but would likely have resulted in unnecessary vendor dispatches. That represents nearly $20 million in R&M spend!

- Misdiagnosis of the issue: Most front-line restaurant employees are not trained to determine what may be wrong with a piece of equipment. As a result, issues can often be misdiagnosed, with multiple technicians sometimes being dispatched before resolving the issue.

- Lack of Visibility & Oversight: Without proper ticketing and communication systems, restaurant employees, vendors, and management cannot effectively validate that work was completed.

- Inadequate Vendor Assignments: It is common for restaurants to have one or two central repair contacts for break/fix scenarios. While reliable and convenient, given the complexity and range of kitchen repairs needed, far too often the wrong person can be dispatched. This increases the time to resolution and usually results in a service fee that produces poor results.

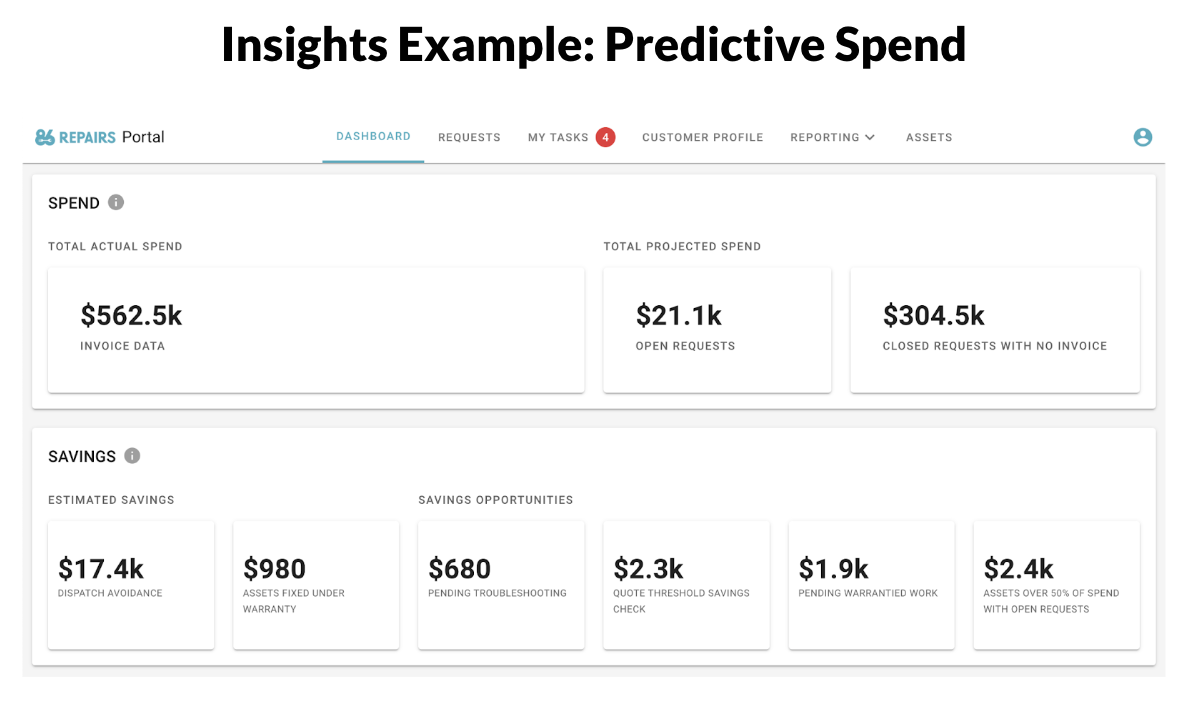

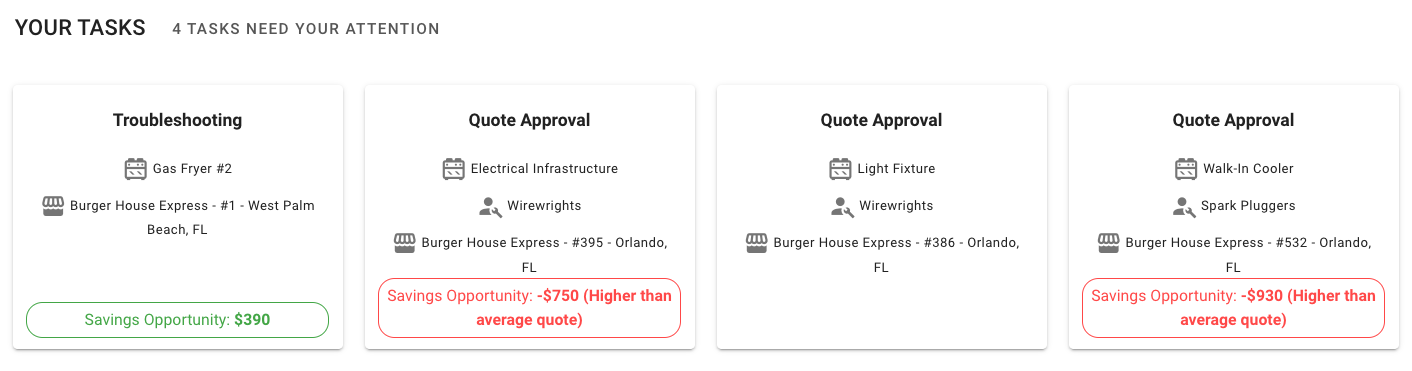

By leveraging predictive analytics and AI, 86 Repairs provides the easiest ticket submission workflow available and forecasts R&M spend for restaurants. Coupled with proprietary troubleshooting & warranty check automation, restaurant staff can submit tickets in less than 20 seconds while communicating accurate details to the right point of contact - every time.

This empowers front-line staff to easily, and consistently, stay on top of R&M while arming restaurant leadership with the key insights and analytics needed to proactively drive down unnecessary R&M costs.

We won’t be coy about it, restaurant management is hard right now, and controlling costs is even harder. But the biggest lever restaurant operators have at their disposal is to proactively control their R&M spend, and 86 Repairs platform was created to allow them to do just that. By having a complete view of your R&M spend, you’ll never overpay for repairs again – and will confidently know you’re taking advantage of every opportunity to save.

If you’re interested in seeing it in action, reach out to our team here.